DTL Thermal 2.0

Price 2200000 INR/ Piece

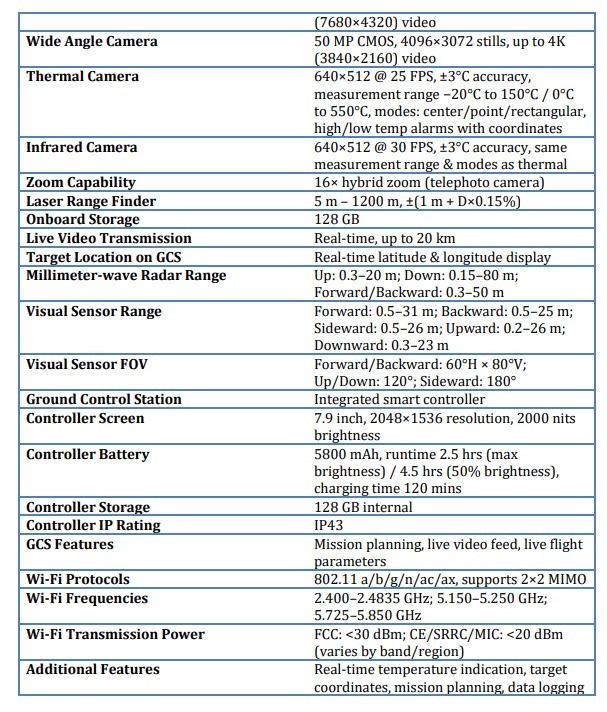

DTL Thermal 2.0 Specification

- Connectivity Type

- USB, Wi-Fi

- Camera Range

- Up to 500 meters

- Camera Type

- Thermal Imaging Camera

- Sensor Type

- Infrared Thermal Sensor

- Camera Style

- Handheld, Portable

- Technology

- Digital Thermal Imaging

- Special Features

- Thermal Imaging, Live Transmission, Compact Design, High Temperature Detection

- Remote Control

- Yes

- Application

- Other

- Camera Size

- Compact

- Camera Pixels

- 256 x 192 pixels Pixel (P)

- Screen Resolution

- 3.5 inch LCD Display, 640x480 pixels

- Image/Video Quality

- High-Resolution Thermal Images, Real-Time Thermal Video

- Power Supply

- Rechargeable Li-ion Battery

- Output Formats

- JPEG (Image), AVI (Video)

- File Compatibility

- JPEG, BMP formats

- Safety Certifications

- CE, RoHS

- Temperature Measurement Range

- -20°C to 550°C

- Working Time

- Up to 8 hours continuous

- Operating Humidity

- <90% RH

- Storage Capacity

- 16 GB Built-In Memory

- Operating Temperature

- -10°C to 50°C

- Dimensions

- 230 mm x 90 mm x 60 mm

- Field of View (FOV)

- 56° x 42°

- Frame Rate

- 25 Hz

- Charging Time

- Approx. 3 hours

- Focus Mode

- Manual

- Temperature Accuracy

- ±2°C or ±2%

- Weight

- Approx. 0.48 kg

DTL Thermal 2.0 Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About DTL Thermal 2.0

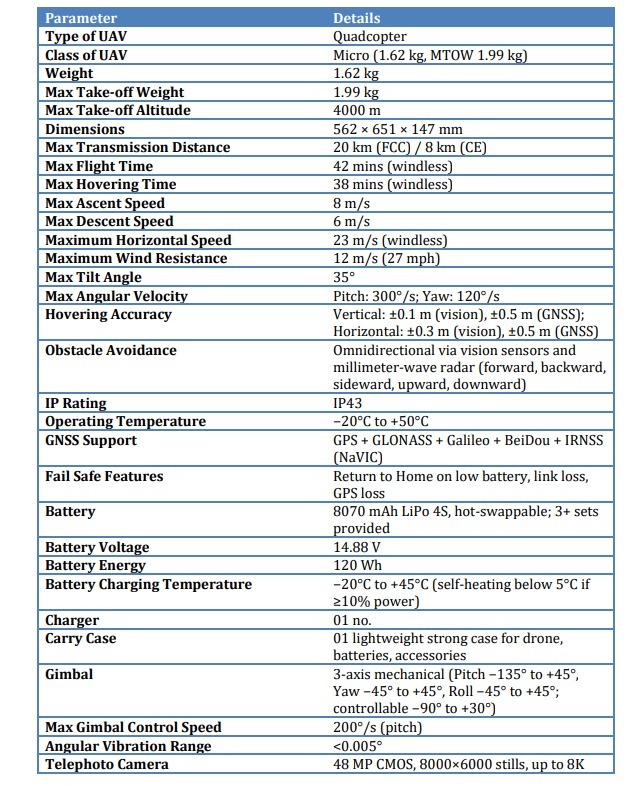

Technical Highlights & Key Features

-

Multi-Sensor Payload Integration

-

Telephoto and wide-angle cameras for detailed and wide-area imaging

-

Thermal and infrared modules for heat mapping, detection, and monitoring

-

Integrated laser rangefinder for precise distance measurement and target acquisition

-

Extended Flight Endurance

-

Up to 42 minutes of continuous operation

-

Hot-swappable battery system enabling rapid turnaround and uninterrupted missions

-

Autonomous Obstacle Avoidance

-

All-weather radar and visual sensing systems for reliable detection and navigation

-

Enhanced safety features for operation in dense or high-risk environments

-

Long-Range and Secure Connectivity

-

Image and data transmission up to 20 km (FCC standard)

-

Multi-band redundancy ensures stable, interference-resistant communication

-

Ruggedized Enterprise Durability

-

IP43-rated protection against dust and water ingress

-

Wide operating temperature tolerance for extreme field conditions

-

Robust, lightweight frame optimized for demanding field deployment

The Thermal 2.0 combines next-generation autonomy, advanced payload integration, and rugged construction, making it an indispensable asset for industries where accuracy, reliability, and rapid deployment are essential.

Advanced Thermal Detection

The DTL Thermal 2.0 employs advanced digital thermal imaging technology, ensuring accurate and rapid heat detection for industrial, electrical, and safety monitoring applications. Thanks to its 256 x 192 infrared sensor and wide 56 x 42 field of view, users can capture high-resolution thermal images and real-time video, even in challenging environments.

Portable and User-Friendly Design

Weighing approximately 0.48 kg and measuring 230 mm x 90 mm x 60 mm, the DTL Thermal 2.0 is crafted for effortless portability. Its ergonomic, compact design allows one-handed operation, enhanced by manual focus and a clear 3.5-inch LCD display. The device operates continuously for up to 8 hours and recharges fully in about 3 hours, ideal for extended field work.

Comprehensive Connectivity and Storage

Equipped with 16 GB built-in memory, USB, and Wi-Fi connectivity, the DTL Thermal 2.0 supports easy storage and seamless data transmission. Photos and videos are saved in JPEG, BMP, or AVI formats, simplifying data management and analysis after inspections. Live transmission and remote control functionalities enhance convenience and productivity on site.

FAQs of DTL Thermal 2.0:

Q: How do I operate the DTL Thermal 2.0 for industrial heat inspection?

A: To operate the DTL Thermal 2.0, simply power on the device, manually adjust focus for clarity, and point it towards the area you wish to inspect. The camera displays high-resolution thermal images and real-time video on its 3.5-inch LCD screen. With up to 500 meters of camera range, it enables safe and comprehensive thermal inspections from a distance.Q: What environments and applications is the DTL Thermal 2.0 best suited for?

A: This camera is ideal for industrial heat inspection, electrical maintenance, building diagnostics, factory safety monitoring, and other settings where monitoring temperature changes or identifying heat-related issues is crucial. Its wide temperature range and certified safety standards allow reliable operation in varied conditions, both indoors and outdoors.Q: When should I use the DTL Thermal 2.0s live transmission and remote control features?

A: Live transmission and remote control are most beneficial when real-time monitoring or team collaboration is needed. For hazardous or hard-to-reach locations, these features allow operators to control the camera remotely and instantly share findings with team members or supervisors, increasing safety and efficiency.Q: Where can captured thermal images and videos be stored and accessed?

A: All images and videos are stored on the DTL Thermal 2.0s built-in 16 GB memory. Files can be accessed directly on the device or transferred to a computer using USB or Wi-Fi, supporting JPEG, BMP, and AVI formats for versatile documentation and reporting.Q: What is the process for charging and maintaining the DTL Thermal 2.0?

A: To charge the device, connect it to a power source using the supplied charger; a full charge takes approximately 3 hours and supports up to 8 hours of continuous use. Maintenance involves keeping the lens clean, regularly updating firmware if available, and storing the camera in a dry place below 90% relative humidity when not in use.Q: How does using the DTL Thermal 2.0 benefit industrial safety and maintenance?

A: The DTL Thermal 2.0 enhances safety by enabling non-contact temperature measurement and early detection of overheating or electrical faults. This reduces downtime, prevents equipment damage, and improves workplace safety by allowing timely preventive actions in hazardous areas.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Survey and Mapping Drones Category

Surveillance & Payload Delivery Drone

Price 800000 INR / Number

Minimum Order Quantity : 1 Number

Warranty : 1 Year

Color : White

Remote Control : Yes

Technology : Bluetooth

10kg Payload Drone

Price 1900000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Color : Black

Remote Control : Yes

Technology : Wifi

FS-SM600 6CH USB Powered Controller with SuperSimX Simulator (Mode 2)

Price 5500 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Color : Black

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese